A Word of Caution

Be careful when working on your guitar. While working on your guitar be careful when you lay it down on your working surface. You can force a string to groove the changer roller if the guitar gets laid on to a hard surface. As you might already know this will ruin the tone of your guitar. This can happen to almost any guitar. Under normal use the rollers will last for years. A .011 or .012 diameter string can create this problem with no trouble at all.

Guitar Tips

Putting on New Strings

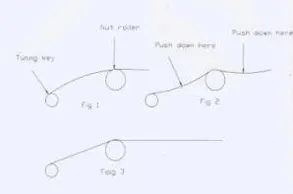

I have been asked several times about gauged rollers on guitars. Our rollers are all the same gauges. This makes it easier to re-install when removed. Since they are all the same gauge you don't have to worry about putting them in the same position on the nut support Here is a simple thing you can do, that I have found to work well after re-installing the rollers or installing new strings. The larger strings on C6th and universal tunings can have the most effect. New strings will create an arc as in figure 1 so you tune the new strings to pitch, push down on points as in figure 2, retune and you will have a nice flat set of strings all across your tuning as in figure 3.

Lubricating Your Guitar

PEDAL ROD LINKAGE

Here are a few points you should lubricate periodically. Do not over do it with lubricating, because it can collect dust and other particles. Once every three to six months depending on how much playing you do and the type of environment you are in.

A small drop of light oil can improve the performance of the roller and eliminate any possible string rattle.

Lubricating the Changer

Occasionally you may have to lubricate the changer system. To lubricate the roller part, it is a must that the strings be remove or loosened to allow the lubricant to penetrate to the areas where it is most required. The area where the string attaches is where all the pressure is generated and the only way to get this area lubricated is to loosen or remove the strings. A good time to do this might be when new strings are being installed. This should be the only place where the changer should need any lubrication. Disassembling of the changer should not be attempted it should be returned to the factory, since there are special tools and fixtures for keeping the components aligned.

PEDAL BALL DISCONNECT

BRASS NUT ROLLERS

CHANGER RETURN STOP SLOTS

New Strings

Here are some tips that might be helpful when replacing new strings. The number 1 problem many players encounter is that annoying third E9th string G#. Breaking it when installed can be eliminated if put on properly. When putting this string on, attach it to the changer and cut it when it extends approximately 2 inches beyond the key head. Put the string through the string post hole and wind 2 turns toward the back side of the guitar and then let the string lap over itself toward the front side of guitar and continue winding until you have it to pitch. Not letting the string lap over itself will cause the string to break, as that small of a string will not bend over that small of a radius without breaking. You should end up having the string as shown in the picture below. With larger strings you should not experience this problem. Larger strings such as 9 and 10 only require one or two turns to work properly without slipping.

Breaking Strings

Breaking strings is a common and annoying situation. You can experiment with different gauges which may help but most string suppliers have charts as to what gauge to use. One thing that is a big contributor to breaking strings is your playing style. Remember the more times you push a pedal or knee lever the sooner you are going to break a string. If you are the only lead instrument in a band, remember that you will be doing all the backup, intro's and instrumental parts so you will have to work your guitar harder which means you will probably break more strings than someone who plays in a band with three lead instruments.

Cleaning Your Guitar

Keeping your guitar clean is a simple matter. Wiping it down with pledge furniture polish is a good solution. If you have something that you cannot remove with polish you can use lacquer thinner on Mica finishes but be careful not to over use it. DO NOT use lacquer thinner on a lacquered or painted finishes. Aluminum parts can be polished with Mothers aluminum polish available at most automotive parts stores.

Adjusting the Half Stop

2nd string half stop adjustment. When assembling new guitars this is the procedure we use when setting up a new guitar for the 2nd string half stop. We use the 9th string for two purposes. The first of course is for the 2nd string half stop and the second is for the D to C# change on the 9th string. To make this work properly use the following method. Make sure that the pulling rods are in the same holes in the bell crank and the changer (this should be the 5th hole, the one that is the furthest from the guitar body) I temper tune the open E9th tuning first and then tune with the pedals down. I next temper tune the 9th string to C# with 6th string having the B pedal down. As the 9th string engages making contact with the changer lowering lever this will apply extra pressure and become the half stop feel for the 2nd string . If properly setup it will all be in tune at this time. We also have available a tunable half stop that is tunable from under the guitar and also you can also adjust the tension as to how hard you want the half stop to feel. For more information on this product e-mail Mullen Guitars at parts@mullenguitars.com

PEDAL STOP ADJUSTMENT SCREW

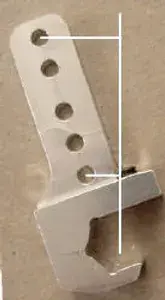

Notice the considerable difference in the amount of movement from top hole as compared to the bottom hole. An example would be such as if you would want to pull the top F# string on the E9th either to G or G#. For the G note you would use the second hole from the bottom as in the picture and for changing to a G# note you would normally use the fourth hole from the bottom. One thing you need to consider is the closer to the end of the bell crank the harder the pedal or knee lever will be to operate.

Adjusting Pedal Travel

Here you will find a simple method for adjusting travel for pedals and knee levers. We will use the typical B pedal raising strings 3 and 6. Back out the nylon tuning nut to be sure it is not pulling against the changer levers and then tune the open tuning. Begin turning the nylon tuner in until the string just begins to raise using the string requiring the most travel (in this example it would be the 3rd string). Back the nylon tuner counter clockwise 2 full turns. Then adjust the pedal stop adjusting screw until that string is in tune. This will set the proper travel and now you can tune the 6th string. In some cases you may prefer to change the pulling point in what is referred as the bell crank. This is the part attached to the hex cross shaft. Moving the pulling rod further away from the guitar body will move the string more as in the example.